For generations, scientists and science fiction writers have contemplated how humans could someday live on Mars. While the idea once seemed like a far-off possibility, the many robotic missions that have travelled to Mars and successfully landed on its surface have given new life to the idea. This presents many challenges, which include the time it takes to reach Mars (6 to 9 months using conventional propulsion) and the dangers of long-term exposure to cosmic radiation and microgravity. But building long-term habitats and facilities on the Martian surface is also challenging.

Simply put, sending rockets carrying all the construction materials, supplies, and machinery needed to build a human outpost on Mars is neither cost-effective nor practical.

For decades, mission planners have researched methods for using Martian resources to meet these needs - a process known as In-Situ Resource Utilization (ISRU). In a recent study, Texas A&M University Professor Congrui Grace Jin and her colleagues from the University of Nebraska-Lincoln present a novel idea that could lead to bio-engineered structures on Mars. The process they recommend was detailed in a paper recently published in the Journal of Manufacturing Science and Engineering.

For years, Jin and her colleagues have worked with bio-manufacturing and living materials, which led to the development of a synthetic lichen system that can produce building materials without human intervention. In their latest study, funded by the NASA Innovative Advanced Concepts program, they demonstrate how this research can be combined with 3D printing to build structures using Martian regolith, sand, and rocks. As Jin said in a Texas A&M press release:

We can build a synthetic community by mimicking natural lichens. We've developed a way to build synthetic lichens to create biomaterials that glue Martian regolith particles into structures. Then, through 3D printing, a wide range of structures can be fabricated, such as buildings, houses, and furniture.

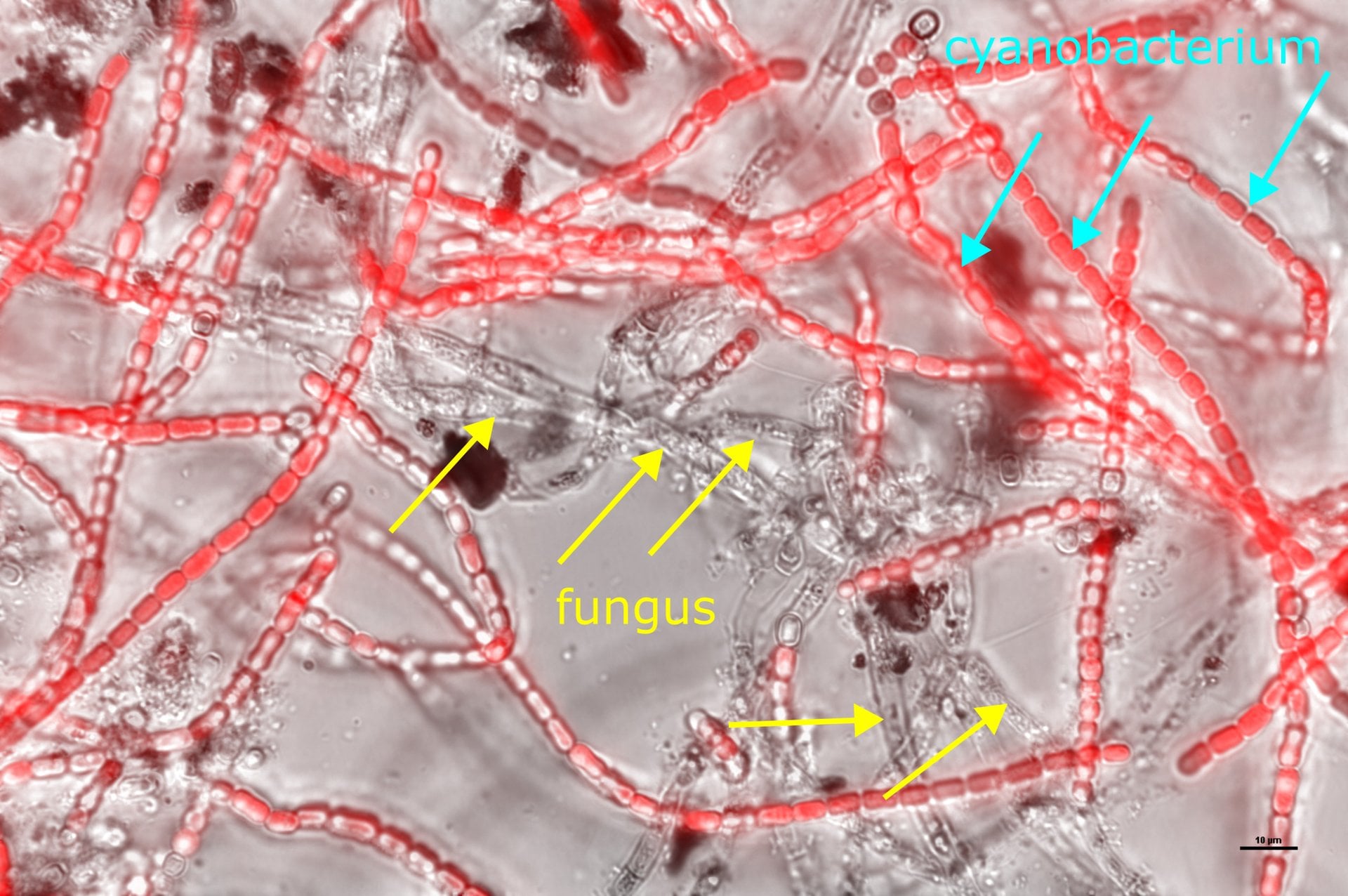

Microscopic view of the synthetic lichen system, in which red-colored fluorescent cells are cyanobacterial cells and the non-fluorescent cells are fungal cells. | Image: Courtesy of Dr. Congrui Grace Jin.

Microscopic view of the synthetic lichen system, in which red-colored fluorescent cells are cyanobacterial cells and the non-fluorescent cells are fungal cells. | Image: Courtesy of Dr. Congrui Grace Jin.

Several methods have been proposed for Martian regolith particles into building materials, including bombarding them with microwaves to create a molten plasma (aka sintering) or using magnesium-based, sulfur-based, or geopolymer bonding agents. These methods are either energy-intensive or require human oversight (or both), making them less practical for long-duration missions to Mars, where resources and the potential for laborers are limited.

Several alternative methods that rely on self-growing technology using microbes have also been developed, like using bacteria to bind sand particles, ureolytic bacteria to promote the production of calcium carbonate to make bricks, and NASA's exploration of the use of fungal mycelium as a bonding agent. Nevertheless, these techniques are not autonomous because the single strains or species of bacteria involved require a continuous supply of nutrients. This means that personnel must be on-site to ensure bacteria get the sustenance they need to do their job.

In contrast, Jin and her team have created a process that relies on two species (diazotrophic cyanobacteria and filamentous fungi) that require only regolith, air, light, and an inorganic liquid medium to grow. First, the diazotrophic cyanobacteria fix carbon dioxide and dinitrogen from the atmosphere and convert them into oxygen and organic nutrients. These help the filamentous fungi grow and increase the concentration of carbonate ions through photosynthesis.

Meanwhile, the fungi bind metal ions onto fungal cell walls, allowing for biomineral production while providing water, minerals, and carbon dioxide for the cyanobacteria. The bacteria and lichens secrete biopolymers that enhance their adhesion and the precipitation of particles that create the necessary structures. This symbiotic relationship ensures that the system can operate continuously and without human oversight, and produces biomineral structures capable of serving the harsh Martian conditions better than other strains of bacteria.

Team AI SpaceFactory's concept, the winner of NASA's 3D-Printed Habitat Challenge. Credit: AI SpaceFactory/Plomp/NASA

Team AI SpaceFactory's concept, the winner of NASA's 3D-Printed Habitat Challenge. Credit: AI SpaceFactory/Plomp/NASA

The technology is nothing short of revolutionary by enabling the creation of structures in the harshest environments where resources are limited. The next step, already underway, is to create regolith "ink" to facilitate construction using the Direct Ink Writing (DIW) method. Also known as robocasting, this 3D printing technique consists of material (or "ink") being printed layer by layer through a nozzle. As with other 3D printing methods, this technology could also have applications here on Earth, particularly in harsh environments where building materials are scarce.

"The potential of this self-growing technology in enabling long-term extraterrestrial exploration and colonization is significant," states Jin.

Their concept, "Biomineralization-Enabled Self-Growing Building Blocks for Habitat Outfitting on Mars," was selected by NASA for a Phase I development as part of the NIAC 2023 Selections process.

Further Reading: Texas A&M University, JSME