Blue Origin is committed to making a permanent human presence in space a reality. To this end, they have developed the New Shepard and New Glenn rockets to send payloads to orbit, and aim to create super-heavy launch vehicles to reach the Moon (New Armstrong and Blue Origin) and beyond. Another focus has been on developing systems that will enable In-Situ Resource Utilization (ISRU) in extraterrestrial environments, which is essential for making space sustainable. This includes their Blue Alchemist ISRU system, which recently completed its Critical Design Review (CDR).

For missions operating beyond Low Earth Orbit (LEO), opportunities for resupply missions will be few and far between. This is especially true where Mars is concerned, since it takes six to nine months to make a one-way transit using conventional propulsion. Ensuring sustainability requires that missions be as self-sufficient as possible, which means relying on local resources to provide basic necessities. This is the purpose of Blue Alchemist, a technology designed to transform lunar and Martian regolith into solar power systems, breathable oxygen, propellant, metals, and construction materials.

Blue Alchemist is an end-to-end, scalable system that relies on a Molten Regolith Electrolysis (MRE) reactor. This reactor uses electrical current to separate oxygen from metals (iron, aluminum, silicon, etc.) without water, toxic chemicals, or carbon emissions. The silicon is then refined to produce radiation-resistant solar cells, while the elemental oxygen can be converted into oxygen gas, fuel cells, or liquid oxygen (LOX) propellant. The metals and ceramics can also be used as building materials for habitat structures and to create semiconductors for electric systems.

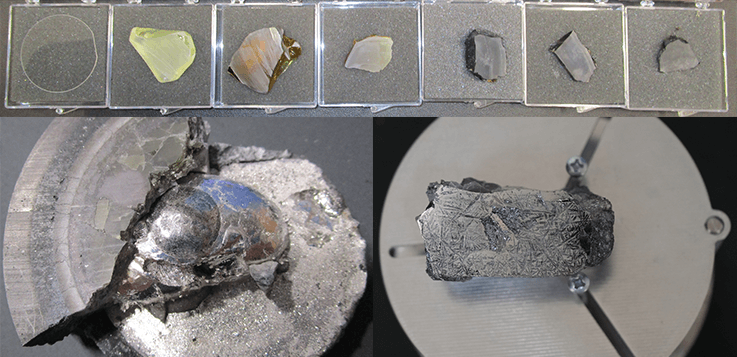

Materials such as iron, silicon, glasses, and ceramics are extracted from our Molten Regolith Electrolysis (MRE) reactor. Credit: Blue Origin

Materials such as iron, silicon, glasses, and ceramics are extracted from our Molten Regolith Electrolysis (MRE) reactor. Credit: Blue Origin

This process reduces reliance on supplies launched from Earth and has potential applications here on Earth, where carbon-neutral manufacturing can ensure sustainable development. Said Pat Remias, the Vice President of Blue Origin's Advanced Concepts and Enterprise Engineering, in a company press release:

Blue Alchemist changes everything about how we approach space. It is the foundation for a sustainable robotic and human presence across the solar system. Each kilogram of oxygen we make on the lunar surface is one less that we have to launch from Earth, making it a giant leap toward permanent settlements as well as critical resources for transportation to the Moon, Mars, and beyond.

The company also indicates that they are on track to scale the system to make lunar landings up to 60% cheaper and reduce fuel cell/battery masses by up to 70% by enabling lunar refueling services. The system is being developed at Blue Origin's Space Resources Center of Excellence (SRCE), a 3-acre facility with 5,575 square meters (60,000 ft2) of lab space staffed by a team of 65 interdisciplinary experts. The technology is being developed with support from a NASA Tipping Point award, which was granted through the agency's Game Changing Development program.

With the CDR completed, Blue Alchemist will move into the next phase of development, with an autonomous demonstration in a simulated lunar environment scheduled for 2026.

Further Reading: Blue Origin